Q&AIWC’s Associate Director Of Research & Development Stefan Ihnen Talks About Innovation And Mastery Of Coloured Ceramics

For a company that boasts a glorious watchmaking legacy of over 150 years, IWC have always managed to stay ahead of the curve by constantly adapting and innovating. This year at the Watches and Wonders fair held in Geneva, they showcased some outstanding new Pilot’s Watches—one of their oldest and core collections—fused with the latest technology in terms of coloured ceramics and in-house mechanics. We spoke to Stefan Ihnen, IWC’s Associate Director Of Research & Development over a zoom video call, where he elaborated on the brand’s pioneering spirit with the use of ceramics coupled with supreme in-house engineering

May We Recommend

What can you tell us about the developments with the ceramic used in the new Pilot’s Watches—the advancements, the technical aspects, the colours, etc?

Coloured ceramics are created by mixing zirconium oxide—a hi-tech ceramic with other metallic oxides. It’s a long and very complicated process, and the colour changes during this firing process. It’s really a lot of effort, needs countless trials and a lot of experience to find the right mixture and afterwards we do colour engineering—where all components of the chronographs are matched to the ceramic—from the dial to the hands to the rubber straps, even with the textile inlay. Even the luminescence material was colour engineered to have this consistent look, running through the watches. The colours of these watches are inspired by the colour codes of the uniforms and the landscapes witnessed by Top Gun pilots. We have computerised this inspiration with the Pantone colour matching system. These new ceramic colours are actually named as IWC Mojave Desert, IWC Lake Tahoe, IWC Woodland, and IWC Jet Black—with number codes, just like how the other shades are named by the company.

What are the challenges faced in developing ceramic that is most suitable for your watches, in terms of durability, scratch resistance and so on?

Ceramic is definitely not easy to handle and it’s a very long and complex process to make ceramic watch cases. Of course in terms of durability and scratch-resistance, ceramic is superior to any other material, however the problem is the lower fracture resistance as compared to metal case construction. IWC Schaffhausen have tremendous experience of working with ceramic and we try to optimise this in the very early stage by putting additives in the basic material, and this is enhanced by the special case construction and design, which differs from how it is normally executed for metal cases. If we compare the ceramic and metal versions of the same chronograph, they will look the same but the inner core will be different.

Is ceramic restricted to just the Pilot’s and Big Pilot’s Watches at IWC Schaffhausen? If not, how do you decide on which collections to use ceramic in? For instance, is it within the realm of possibility to come out with a Portugieser or a modern Da Vinci in ceramic?

At IWC Schaffhausen, ceramics are not just restricted to Pilot’s Watches. When we look back at our history, the first ceramic watch from IWC Schaffhausen was a Da Vinci model. The only watch made from the hardest ceramic in the world—boron carbide—was an IWC Ingenieur. So it’s not just limited to Pilot’s Watches but ceramic has found its place in the sporty and performance product lines.

IWC Schaffhausen enjoy admiration for being pioneers in ceramic, and for being at the forefront of using this material. How do IWC’s ceramics stand apart from those used by other leaders in ceramic, such as Hublot and Rado?

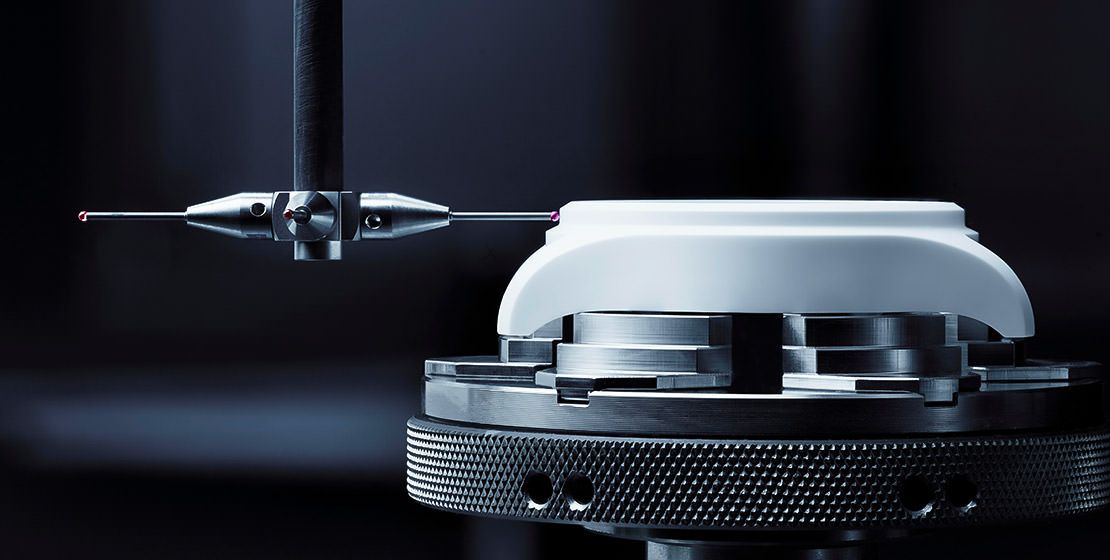

We were the first brand to use ceramic in our watches, and bring them on the market, especially with coloured ceramics. We not only have mastery of working with zirconium dioxide—the most largely used ceramic in the watch industry, but we have also mastered the use of other high-tech ceramics such as silicon nitride and boron carbide—we have a patent on cases crafted from this. We are very experienced in creating comfortable case designs with ceramic. And not only this, I think we are the only brand that uses ceramic for movement parts as compared to others who use it in the ball bearings. For example, our Pellaton winding system consists of ceramic clicks and automatic wheels for over ten years now, and in doing so we have created a wheel-free automatic winding system. So that’s how I feel IWC Schaffhausen is ahead of its competitors by way of development, case construction and movement—where it really makes sense since there is constant wear and tear, and ceramic makes the components more long-lasting.

Coming to this aspect that you just highlighted that it’s not just in the case construction but also in the movement that IWC Schaffhausen has been using ceramics. How does this give the brand an advantage, and what is more challenging—using ceramic in the case construction or within movement parts?

It’s tough to choose between the two aspects whether it’s using ceramic in the case construction or applying it to movement components. In the movement, one has to be more precise while using ceramic but the advantages it brings outweighs the challenges while incorporating this material into something that’s so technical. Over the years, we have also realised that sometimes combining several small parts together to create one big component also works better inside a watch. For example we have executed this method in creating the bearings of the Pellaton winding system. When it comes to watch cases, colour engineering plays a huge role, which is not important for the movement, where we generally use white or black ceramic. The process of combining ceramic with other materials or metals is the tricky part because when you start, you never know the end result. Hence it requires major expertise in terms of research and development to create coloured ceramics and also maintain consistency, so that each time we get the same hue.

With research and development, is it more challenging to work on movements and complications, or on materials? Which is more exciting?

I am a trained watchmaker and have spent considerable amount of time in movement development. If you would have asked me a few years ago, then my answer would have been movement creation is a more complex aspect and probably more exciting. But in the last decade, at IWC we have made some great advancements when it comes to case construction. We developed Ceratanium—a very challenging experience to create our own in-house material, which combines titanium with ceramic. It’s difficult for me to choose now as both are very different but challenging in their own right. And I think both aspects when combined add to the excitement of creating a timepiece that really stands out.

What are the challenges you face with being innovative, while also staying true to IWC Schaffhausen’s DNA—staying within the brand’s guidelines, and taking forward the brand’s existing signature features, designs and so on?

There are internal discussions many times where we find ourselves questioning whether we are on the right track, but when I look at everything, I think we’re doing well. For instance, look at the Pilot’s Watches this year. It’s pure IWC DNA and one can just tell our watches apart from others. We have stuck to our design codes, which has remained largely unchanged ever since our Pilot’s Watch collection came into existence. Even though we have innovated in terms of equipping our watches with in-house movements, new materials, and coloured ceramics; we have ensured to not stray from our watchmaking heritage and design expertise.

Coming back to focus collections and deciding on the right time for launching new editions, how do you decide on the time being right for any given collection? Is there a chance we’ll see new editions of the Aquatimer or Ingenieur or even Da Vinci any time soon?

There are frequent internal meetings where we decide upon the product strategy with our senior management. These are based on certain internal assessments and market insights. That’s why this year we are focusing on Pilot’s Watches—and our new models have received a great response. Maybe next year there will be something else but there’s no clarity on it as of now.

Found your post interesting to read. Good Luck for the upcoming update.This article is really very interesting.