FeatureGems Of Time: The Jewels That Keep A Watch Moving

Discover why jewels are integral components in a mechanical watch movement, and how they're incorporated into the mechanism

May We Recommend

Jewels or gemstones were introduced in watch movements to reduce friction at points of heaviest wear and tear. When metal rubs against metal, and when oil meant for lubrication breaks down, the damage to pivots and bearings can be severe. In order to reduce friction between two metal components that rub against one another, watchmakers use hard stones at the points of friction as they last a lot longer than metal.

Between A Rock And A Hard Place: The Types Of Jewels In Watches

To reduce metal-on-metal wear and tear, watchmakers needed to find a substance that was harder than metal and so began the use of jewels within watch movements. The jewels that are hard enough are diamonds, sapphires and rubies. The latter two were cheaper than diamonds and could also be synthetically created. Rubies are used more often because their Mohs scale measurement is similar to diamonds. (Mohs is a scale used to measure the relative harness of a mineral, based on its resistance to scratching.) These days there are synthetic rubies created which do the work of natural jewels in watches quite well. It was initially quite difficult to create and set these jewels. The number of jewels in a movement was a true indicator of its quality.

Movements Embellished

In most watches the jewels are used for all the pivot points in the gear train, as well as in the anti-shock settings. As watches became complicated, the number of jewels gradually increased in numbers. With jewels getting easier to produce and set, and with marketing in the watch industry getting better, watchmakers started jamming up watches with jewels in places where they weren’t even needed. The use of jewels was heavily marketed to make the watches seem to be of a higher quality than they actually were. So when you see watches with say, 85 jewels or so, you know you are being taken for a ride.

The First Jewels In Movements

Nicolas Fatio de Duillier, Peter Debaufre, and Jacob Debaufre introduced jewel bearings for use in watches way back in 1704 and also received an English patent for the idea. It made a lot of sense as many gemstones are much harder than metal, especially diamonds, but also sapphires and rubies (corundum), which are identical in makeup except for their colour. They are also slicker than metal, which means they manage to protect vulnerable areas while encouraging a smoother, less-damaging process in the first place.

Another thing to consider is different movement designs warrant different numbers of jewels. An automatic movement will have additional moving parts that would require more jewels to reduce friction. The automatic movement works are under heavy wear and tear, as the rotor spins almost constantly to transmit power to the mainspring.

Resilience Of A Jewel

Talking about sapphire the crystalline nature of the stone lends itself to very fine polishing. The sapphire surface has excellent oil and lubricant-retention ability. Sapphire’s extreme hardness imparts to the bearing excellent wear resistance, as well as the ability to withstand heavy loads without deformation. An excellent example of that are the Bulova 21-jewel automatic watches of the 50s and 60s, which have proven their jewelled reliability, and have stood the test of time, offering accuracy for over 50 years, despite never having been serviced.

In 1974, 270 years after the first patent for jewel bearings, the use of functional jewels in watchmaking was standardised by the International Standards Organization (ISO). As per ISO 1112, a functional jewel was defined as one serving ‘to stabilise friction and reduce the wear rate of contacting surfaces of the components of a timekeeping instrument’.

Jewels That Protect

A mechanical movement is composed of moving parts, such as gears, wheels and pinions. These parts rotate on pivots, the vertical axes crossing the wheel. However, one has to consider that, for example, the fourth wheel of a watch makes a full circle on its axis, once per minute, making 1,440 full rotations a day or 5,25,600 full rotations a year. Thus, the forces applied on the axis of such a wheel, even if it’s small and light, are enormous. This is why it is harmful to insert the axis of such a wheel directly in the main-plate of the movement – considering the metal-vs-metal friction. Even with modern lubricants, the axis can slow down the movement of the wheels – ruining the accuracy of the watch – and at some point, wheels will simply get blocked. The solution – jewel bearings, which allow low friction with metal pivots. They also possess excellent temperature stability and are acid-resistant.

The pivots and jewel bearings of the balance wheel are especially fragile and would often get damaged under impact. They were a major cause of repair. With anti-shock systems, the jewels are mounted on springs allowing them to shift in their setting, in order to absorb radial or axial shocks. Incabloc, Kif or Etachoc are the more common shock protection systems for Swiss movements.

The Distribution Of Jewels And How Many Jewels Are Used In Movements

The most common jewels used in a watch are:

- Doughnut-shaped jewels that fit over the gear axles or arbours

- Flat-cap jewels that are placed at the end of the axles

- Brick-shaped pallet jewels that alternately engage and release the escape wheel

- Roller jewel on the large balance wheel that swings back and forth.

The jewels are shaped so that the capillary action of the oil causes it to be drawn towards the gear axles instead of spreading all over.

The jewels are located at all the key spots covering the watch:

- The basic seven jewels are a part of the escapement and balance. They include cap and hole jewels for top and bottom of the balance wheel (four in total), the two pallet jewels and a roller jewel.

- The next eight are hole jewels for the fast-moving parts of the gear train.

- The next two are jewels on the centre wheel.

- The next 2 to 4, taking the count to 19 to 21 jewels are cap jewels on the escape wheel and the pallet.

Additional jewels are often needed to make automatic watches efficiently transfer the small amount of power generated by the movement of the wearer’s wrist into the power needed to wind the watch. More jewels are often used for chronograph functions, time repeater chimes, and date/date displays. Very complicated watches can have over 40 functional jewels.

Quality Over Quantity

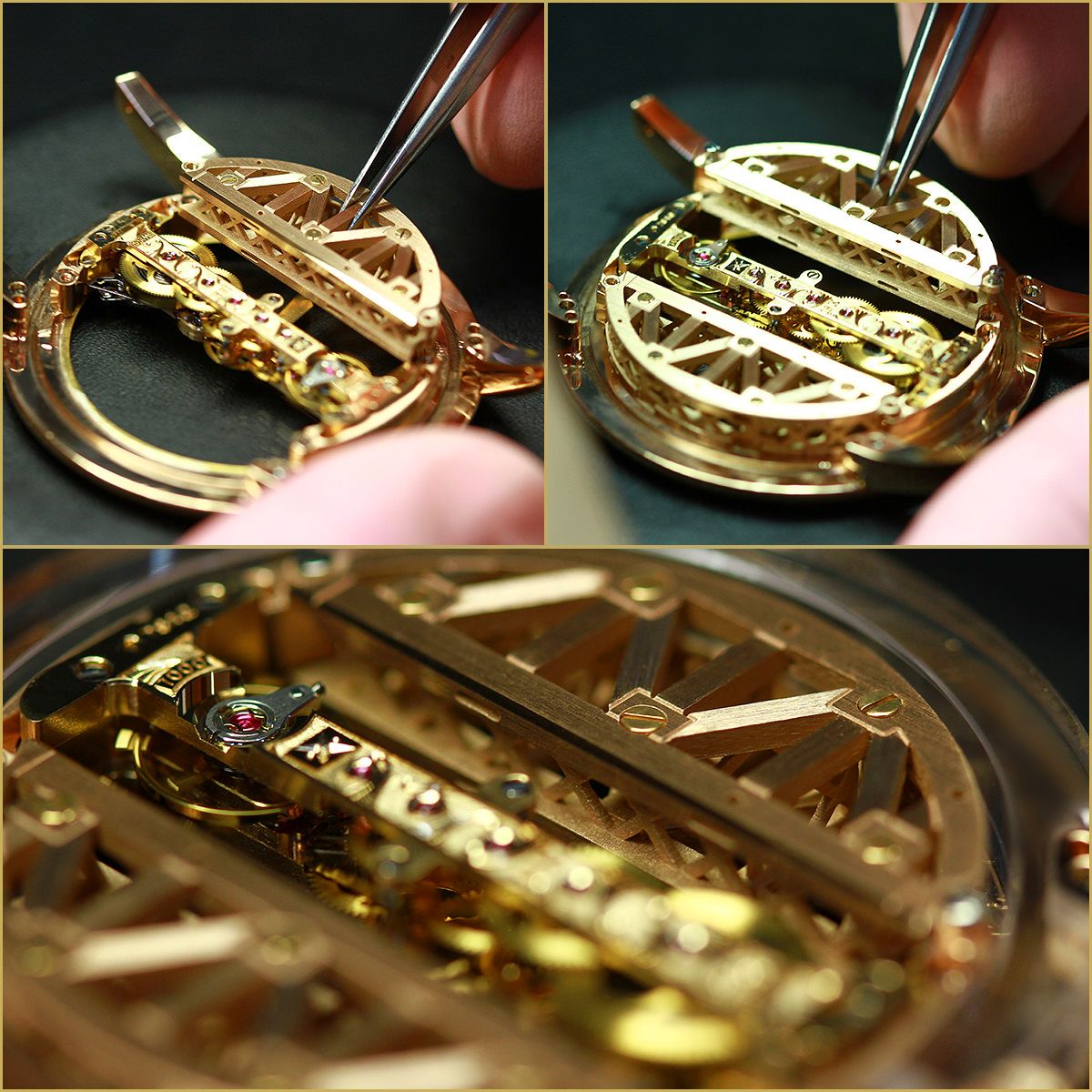

In conclusion, jewels ensure that a watch can function for longer periods until it requires servicing, and that the damage to high wear-and-tear points is greatly reduced. It is worth noting that some brands have brought back the use of chatons – a difficult technique where small brass or gold settings are used to fit the jewel into the movement plate – and in some watches the setting of jewels is almost an art form. Lastly, it is important to note that while it is true the number of jewels in a movement once spoke to its quality or complexity, today that isn’t very true. Watch collectors are less interested in jewels today as they are now easy to include and are produced from synthetic materials.

FAQs

1. Does a greater number of jewels in a watch make it better?

There is no direct coreelation between the quality of a watch and the number of jewels in its movement. The jewels do impact the quality of a watch, but the construction of a high-end movement, which does not have as many friction points, may not require as many jewels as a lower-end movement that has a lot of friction points. This would mean that the former has fewer jewels, but is still better in quality.

2. Do all watches have jewels?

All watches do not necessarily have jewels. In fact, with metallic parts being replaced with other materials, such as silicon, the requirement of jewels has reduced in such kinds of watches.